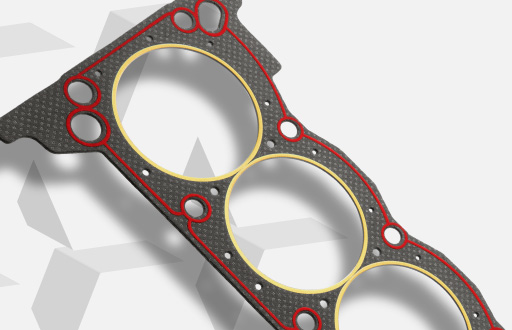

Seals the cylinder head and engine block, preventing coolant, oil, and gas leaks while maintaining engine efficiency.

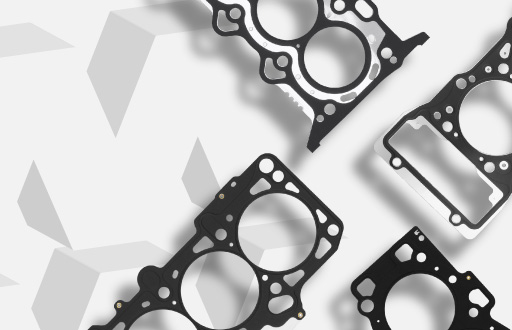

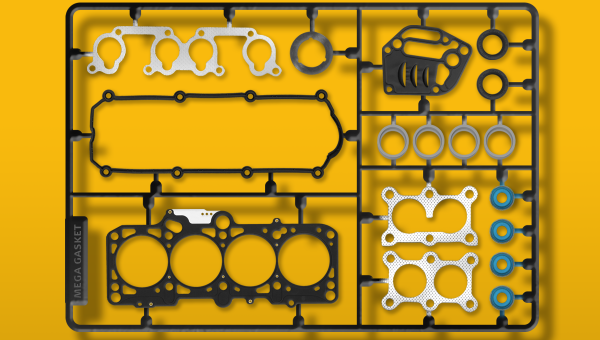

Engine Gasket Kits

An engine gasket kit is a crucial collection of seals that prevent leaks and maintain engine integrity. It typically includes gaskets for the cylinder head, intake and exhaust manifolds, valve cover, and oil pan. These components ensure optimal engine performance by preventing oil, coolant, and gas leaks. Whether for routine maintenance or a full engine overhaul, gasket kits and sets provide the necessary seals to keep engines running smoothly and efficiently.

To our customers, Mega gaskets offer several types of engine gasket kits and different engine gasket sets for Japanese, Korean, European, and American vehicles. By using high-quality engine gasket kits made from Taiwan, your car engine could obtain better protection from leaking.

|

Japanese and Korean Cars |

European and American Cars |

||

Questions about MEGA Engine Gasket Kits

1.How to order MEGA engine gasket kits?

A: You can visit our catalog on official website (https://www.megagasket.com/en/catalog) to tick the items you need and send the inquiry list, or send email to mega999@ms36.hinet.net. Please provide OEM and engine number for us to check.

2.What to do if you cannot find our engine gasket kit model on MEGA website?

A: You can provide the sample for MEGA. We will evaluate if we can develop the product and then quote the price.

3.Does MEGA engine gasket products come with warranty??

A: Under normal usage, standard products (non-customized) provide one-year warranty, or mileage is under 10000 kilometers.

4.Does MEGA provide the engine gasket kit sample?

A: MEGA can provide the sample and charge it in advance. But if you place the follow up order, we will deduct it from the order.

5.Does there is MOQ for each engine gasket kit?

A: If there is inventory, MEGA does not have MOQ, but if there is no inventory, we will set MOQ by each item.

Ensures airtight sealing for proper airflow and prevents gas leaks between the manifolds and engine block.

Prevents oil leaks between the valve cover and cylinder head, keeping the engine clean.

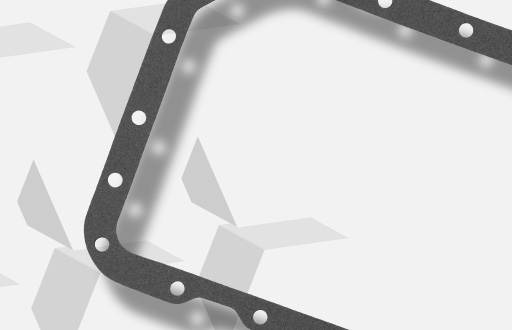

Seals the oil pan to the engine block, preventing oil leaks and ensuring proper lubrication.

Other Gaskets/ Parts

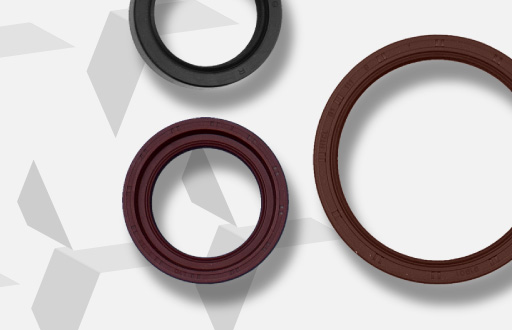

Prevents oil leaks in rotating components like the crankshaft, ensuring efficient engine operation.

Prevents oil from leaking into the combustion chamber, maintaining compression and reducing oil consumption.

Gasket Material

The parts in engine gasket kits are different materials of seals to prevent from leaking oil and gas at engine junction.

Choosing gasket material will significantly impact how the material performs in the intended application on your vehicle.

MEGA provides types of gasket materials to select for building your vehicle gasket, each with several tolerances for you to choose.

Below we provide graphite gasket material, metal/steel gasket material, and non-asbestos(asbestos free) gasket material.

Pick the gasket material with the right thickness and longevity

Metal Gasket/Steel Gasket Introduction

The term ‘metal gasket’ is used to describe a variety of parts, which create a seal between joined components. Gaskets are used across a broad spectrum of industries and applications. Metal gaskets are made from metallic materials. Gaskets, shims and washers can be manufactured using different metals to cater to a diverse range of environments and applications. In this guide, we’ll explore metal gaskets in detail, discussing the most common materials and how they are used.

What is a metal gasket?

A metal gasket is a mechanical seal, which is manufactured using metals or metal alloys. Gaskets have a huge range of uses across industries, including automotive design and manufacturing, engineering, construction, pharmaceuticals and energy.

What is a metal gasket used for?

The primary use of metal gaskets is to create a strong seal. Gaskets are used to create a barrier, which separates different materials or chemicals and prevents friction between moving components. Strong, properly fitted and maintained gaskets prevent leaks to boost performance, prevent damage, increase energy efficiency and shield surrounding parts.

About the metal gasket type

There are several different types of metal gaskets, which include solid metal gaskets and jacketed metal gaskets. Solid gaskets are created using metallic materials while jacketed gaskets contain a different material, which is wrapped in an external layer of metal. The choice of materials will usually depend heavily on the environment and the application. Examples of gasket types include:

- Envelope

- Corrugated metal

- Flat metal

- Non-asbestos

- Ring-type

- Spiral wound

- Kammprofile/Camprofile gaskets

- Serrated

What are the most common metal gasket materials?

Gaskets are made using a wide variety of metals, including:

-

Copper

Copper is often recommended for applications and environments that involve exposure to steam. Copper has a maximum temperature of 400 degrees Celsius and it is most commonly used for small gaskets with limited seating stress.

-

Stainless steel

There are several different types of stainless steel that are used to manufacture gaskets. The type reflects the hardness, maximum temperature, resistance to corrosion and pressure capabilities. Types of stainless steel gaskets include:

- 304

- 316

- 321

- 347

- 410

- 430

Stainless steel 304 is an all-rounder, which is commonly used in industrial applications. The hardest types are stainless steel 321, 347 and 410. The most resistant against corrosion are types 347, 316 and 304. Type 321 is suitable for high temperatures up to 760℃.

-

Carbon Steel

Carbon steel is usually used in applications, which involve liquid hydrocarbons. It is softer than other metals and will corrode when exposed to water.

-

Nickel

Nickel has a high operating temperature and it offers relatively good erosion and corrosion resistance.

-

Aluminum

Aluminum is a popular choice for gaskets used in the manufacturing industry due to its powerful resistance to corrosion. It is also an easy metal to use, which makes it more appealing than other materials.

Metal gaskets applications and uses

Metal gaskets are made from a single metal or a combination of metals. They provide greater heat, erosion and corrosion resistance than non-metallic materials and are often chosen for high stress or pressure environments and applications that involve chemical exposure or extreme temperatures.

Metallic gaskets are commonly found in the following applications:

Metallic gaskets have a huge range of uses across a broad spectrum of industries.

- Condensers

- Heat exchangers

- Compressors

- Pumps

- Valves

- Turbines

- Steam applications

- Offshore oil and gas pipelines

Industries that use metal gaskets include:

- Automotive

- Energy

- Food production and storage

- Aerospace

- Manufacturing

- Transport

- Medicine and pharmaceuticals

What are the advantages of metal gaskets?

Several materials are used to create gaskets. Metal gaskets are often the best choice because they offer wide-ranging benefits that make them suitable for a diverse range of environments and applications. When compared to non-metallic materials, metals offer the following advantages:

5 Benefits of Metal Gasket Material

- Withstanding high temperatures up to over 1,000 degrees Celsius

- Chemical resistance

- Boundless pressure capabilities

- Resistance to environmental conditions and changes in weather and climate

- Ability to enhance capabilities by creating metal alloys: alloys can offer additional benefits to single metals

How to choose the right metal gasket for your application

Choosing the right metal gasket material is essential to ensure optimum performance and safety. Metal gaskets are used across a huge range of applications, and one material may be better suited to a specific environment or function than another. It is important to consider the following factors when choosing metal gaskets:

- The environment or setting

- The application

- The type of seal required

- Pressure resistance

- Surface evenness

- Exposure to fluids and environmental contaminants

- Temperature

Selecting the right material for a gasket is key to successful operation. With a vast array of metal gaskets available, it can be difficult to determine which material is best if you are not an expert in this field. If you are looking for gaskets for a specific project or application, and you’re unsure which material to choose, it’s wise to seek advice. If you make the wrong selection, there is a risk of leaks, accelerated wear and tear and compromised performance. Ill-fitting gaskets and using materials that are not suitable for the environment can also cost you more money in the long term.

Related article:Concise Gasket Material Types For Gasoline And Selection

Need help finding the right metal gasket material?

MEGA Metal Gasket Supplier

The MEGA Gasket team has extensive experience in engine gasket kit and metal gasket and providing tailored advice and solutions for clients operating across a variety of industries. If you need help or advice, don’t hesitate to get in touch. We can provide customized advice and recommendations based on your requirements and the demands of the individual project. Contact us today by filling in this quick and easy online enquiry form.

CONTACT US This email address is being protected from spambots. You need JavaScript enabled to view it.

What is asbestos free gasket?

An asbestos-free gasket is a type of gasket that does not contain asbestos as one of its components. Asbestos, once commonly used in gaskets for its heat resistance and sealing properties, is now recognized as a hazardous material. To prioritize safety, MEGA Gasket, a leading gasket manufacturer in Taiwan, specializes in producing asbestos-free gaskets. These gaskets are made from non-asbestos materials, such as synthetic fibers, elastomers, graphite, or other combinations, that provide similar sealing performance without the health risks associated with asbestos.

Advantages of Asbestos-Free Gasket Sheets

Asbestos-free gasket sheets offer several significant advantages over traditional asbestos-containing gaskets:

-

Environmental and Health Safety

Unlike asbestos gaskets, which pose serious health risks due to harmful fiber inhalation, asbestos-free gaskets are made from safe materials, eliminating such hazards.

-

High-Temperature Resistance

Non-asbestos gaskets are engineered to withstand elevated temperatures. For instance, certain grades can operate continuously at temperatures up to 250°C, with peak temperatures reaching 400°C.

-

Chemical Resistance

These gaskets exhibit strong resistance to various chemicals, enhancing their durability and performance in chemically aggressive environments. They are suitable for sealing against oils, solvents, fuels, and other non-aggressive solutions.

-

Excellent Sealing Performance

Asbestos-free gaskets provide reliable sealing capabilities, effectively preventing leaks and maintaining system integrity under various operating conditions. They are designed to offer good impermeability to gas and exhibit good recovery properties.

-

Versatility and Adaptability

Manufactured from diverse materials like aramid fibers, graphite, and PTFE, non-asbestos gaskets can be tailored to meet specific application requirements. They are used in air compressors, diesel engines, pipelines, and many other general industrial and marine environments.

By adopting asbestos-free gasket sheets, industries can enhance operational safety, comply with health regulations, and achieve reliable sealing solutions without compromising performance.

Materials Used in Non-Asbestos Gaskets

Non-asbestos gaskets are engineered using a combination of materials to replicate and often surpass the performance of traditional asbestos gaskets. The primary materials include:

Aramid Fibers

Known for their exceptional strength and heat resistance, aramid fibers provide structural integrity to gaskets, enabling them to withstand high-pressure and high-temperature environments.

Synthetic Fibers

Materials such as glass fibers and mineral wool are incorporated to enhance the gasket's durability and resistance to various chemicals.

Elastomers

Binders like nitrile butadiene rubber (NBR) are used to impart flexibility and improve sealing capabilities, allowing the gasket to conform to flange surfaces effectively.

Graphite

Utilized for its excellent thermal conductivity and ability to withstand extreme temperatures, graphite enhances the gasket's performance in high-temperature applications.

Applications of Non-Asbestos Gasket Materials

Non-asbestos gasket materials are utilized across various industries due to their safety and performance benefits. Key applications include:

- Automotive Industry: Employed in engines, transmissions, and water pumps, non-asbestos gaskets play a crucial role in enhancing emission standards and vehicle safety.

- Chemical and Petrochemical Industries: These gaskets are essential for sealing pipelines and equipment, effectively preventing leaks in the transportation and processing of chemicals and oil.

- Marine Applications: Utilized in ship engines and offshore installations, non-asbestos gaskets ensure reliable sealing under harsh marine conditions.

- Power Generation: Power plants rely on these gaskets to maintain system integrity, ensuring efficient operation of turbines and other critical equipment.

- HVAC Systems: In heating, ventilation, and air conditioning systems, non-asbestos gaskets provide airtight seals, contributing to energy efficiency and system reliability.

Need Help Finding the Right Asbestos-Free Gasket?

The MEGA Gasket team has extensive experience in asbestos-free gasket and providing tailored advice and solutions for clients operating across a variety of industries. If you need help or advice, don’t hesitate to get in touch. We can provide customized advice and recommendations based on your requirements and the demands of the individual project. Contact us today by filling in this quick and easy online enquiry form.

CONTACT US This email address is being protected from spambots. You need JavaScript enabled to view it.

Interface Material

The Interface material that MEGA uses is aiming to help customers meet their requirements for performance improvement, the certainty of operation, and easy installation

Rubber Parts

We also offer a variety of rubber parts materials, including VITON, ACM, Silicon, and NBR. Our rubber parts materials are from a wide range of grades, each of which offers different characteristics and makes it suitable in different situations.